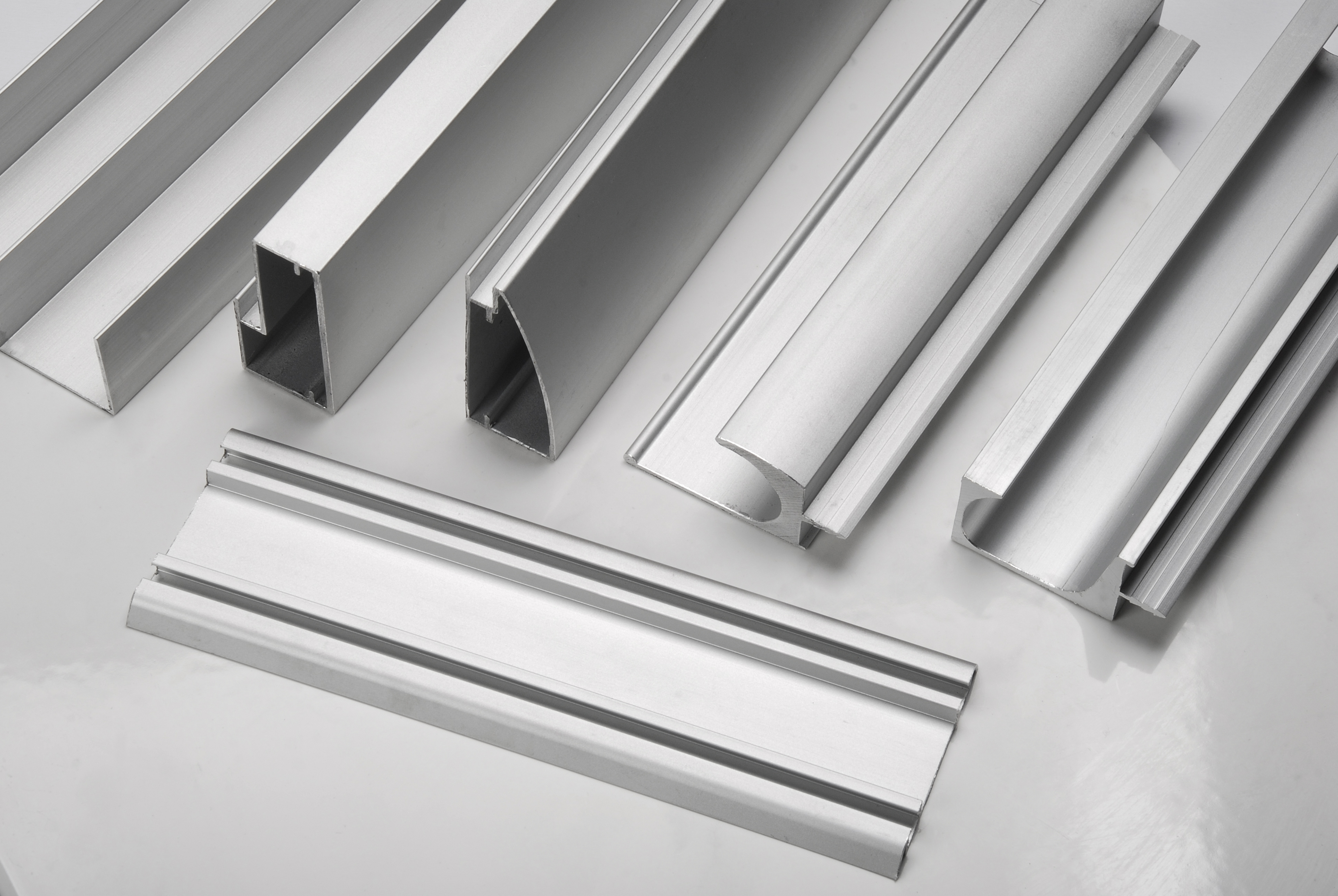

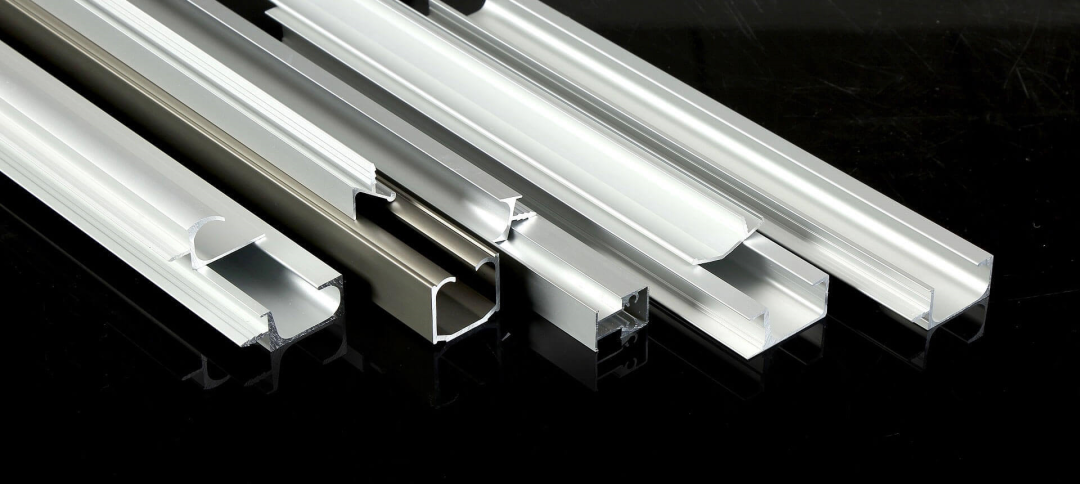

Aluminum abu ne mai mahimmanci na asali.A cikin rayuwar yau da kullun, sau da yawa muna iya ganin amfani da bayanan martaba na aluminum a cikin ginin kofofin,tagogi, bangon labule, kayan ado na ciki da waje da tsarin gine-gine.

Bayanan martaba na aluminum na gine-gine suna da ƙayyadaddun buƙatu don daidaitawa da samar da taro, kuma yawanci ana amfani da tsarin extrusion na aluminum don cimma ingantaccen bayani don samarwa da masana'antu.Mahimmin ra'ayi na extrusion bayanin martaba na aluminum shine a yi amfani da wani matsa lamba akan sandar aluminum a cikin ganga na extrusion don sa aluminium alloy ya gudana daga wani rami mai mutuƙar ƙayyadaddun, don haka samun bayanan martaba na aluminum na takamaiman siffofi da girma.Wannan hanyar sarrafa extrusion yana da ƙarancin farashi, babban inganci da aiki mai sauƙi, kuma yana ɗaukar babban rabo a cikin tsarin samar da masana'antu na zamani.Wannan labarin zai mayar da hankali kan tsarin samar da extrusion na bayanan martaba na aluminum, yana ba mu damar samun zurfin fahimtar samfuran bayanan aluminum:

1. Samar da albarkatun kasa

Dangane da ƙididdigar ƙididdiga na bayanan bayanan aluminum da ake buƙata, nau'ikan albarkatun ƙasa daban-daban suna sanye take da kyau.Aluminium ingot yana mai zafi zuwa wani zafin jiki don narkewa, kuma ana ƙara wasu adadin abubuwan alloying zuwa narkakken ruwa na aluminium (magnesium da silicon. yawanci ana ƙara zuwa ƙofar tsarin da layin samfurin taga).Ana cire slag da iskar gas a cikin narke ta hanyar daidaitattun hanyoyin daidaitawa.A ƙarƙashin ingantattun yanayin aiwatar da simintin gyare-gyare, ana zubar da ruwa na aluminum mai narkewa a cikin injin simintin, sanyaya kuma jefa cikin sandunan simintin zagaye tare da diamita da ƙayyadaddun ƙayyadaddun da suka dace da tsammanin.

① Sanya sandunan aluminium a kan tarkacen kayan, kauce wa kasancewa kusa da juna ko tara su, da ajiye sararin aiki mai aminci don hana sandunan aluminum daga mirgina ko ma fadowa.

② Zazzage sandar aluminum da mold a cikin tanderun don ɗaga zafin jiki zuwa 480 ° C, kuma kiyaye shi dumi don 1 hour kafin aiki na gaba;

③ Sanya mold a cikin tushen mutuwa na extruder, sanya sandar aluminum a cikin tashar abinci na extruder kuma shirya don extrusion;

④ Fayil ɗin da aka fitar yana fitowa daga ramin fitarwa, kuma an ja kayan kai ta tarakta, kuma ana aiwatar da yankan farko bisa ga tsayin da aka saita da girman.

3. Daidaitawa

Bayanan martabar aluminum da aka zana ta hanyar extrusion yawanci ba sa saduwa da daidaitattun daidaito, wanda ke shafar amfani na gaba ko aiki a kan kayan aikin injiniya. Ana aika bayanan bayanan aluminum da aka fitar zuwa teburin daidaitawa don daidaitawa, sa'an nan kuma an kai shi zuwa yankin da aka gama don yankewa zuwa tsayi.

4. Magani akan lokaci

Saka kayan bayanin martaba na aluminum alloy a cikin tanderun tsufa don dumama shi zuwa wani zafin jiki da kuma kiyaye shi dumi na tsawon sa'o'i 2-3 zai iya inganta haɓakar kayan aikin injiniya na bayanin martaba na aluminum alloy, musamman ma ƙayyadaddun kaddarorin. Sanya bayanan bayanan aluminum da aka yanke a cikin firam ɗin kayan aiki, jigilar su zuwa yankin tsufa, kuma shigar da tanderun tsufa don maganin tsufa na hannu.Lokacin da yawan zafin jiki ya kai 200 ℃, sai a dumi shi tsawon sa'o'i 2, sannan a jira a sake shi, bayan an gama tsufa, ana iya fitar da shi daga cikin tanda a shiga cikin yanayin sanyaya.Ana iya kwantar da shi ta dabi'a ko ta wucin gadi tare da mai sanyaya iska.A wannan lokaci, aikin extrusion ya ƙare, kuma ƙaddamar da bayanan martaba na aluminum tare da ingancin bayyanar da siffar da siffar da girman ya cika.

5. Maganin saman

Aiwatar da maganin da ya dace kamar yadda ake buƙata.A halin yanzu, akwai da yawa rare surface jiyya matakai a cikin tsarin kofa da taga masana'antu: anodizing, electrophoresis, ain shafi, fluorocarbon spraying, da dai sauransu.

Tuntuɓi tare da us don ƙarin bincike.

Tel/WhatsApp: +86 17688923299

E-mail: aisling.huang@aluminum-artist.com

Lokacin aikawa: Agusta-31-2023