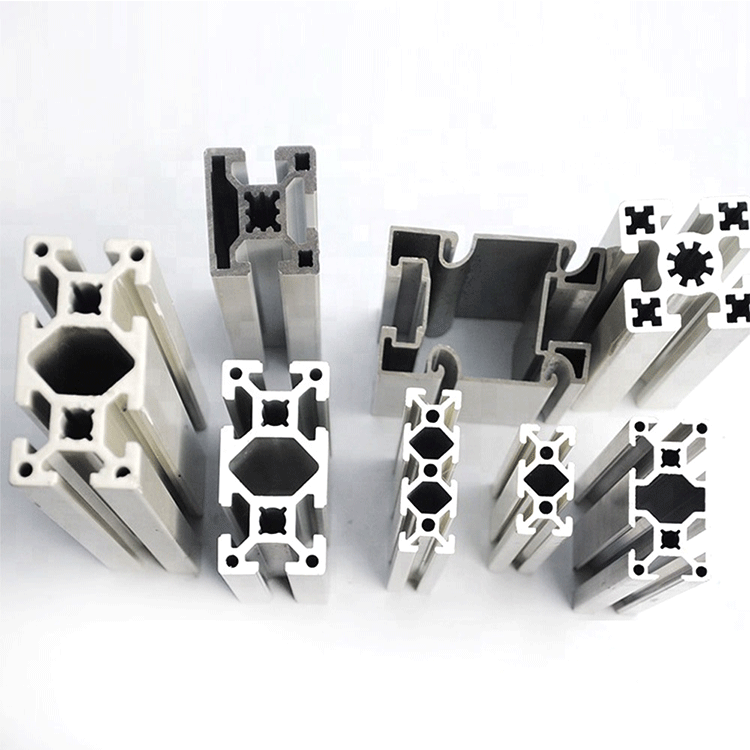

T-slot aluminum profiles ana amfani da ko'ina a masana'antu masana'antu, inji kayan aiki, da kuma aiki da kai tsarin saboda su high ƙarfi, nauyi Properties, da versatility. Kuna buƙatar ɗorewa, babban aiki na al'ada T-slot profile aluminum don aikinku na gaba? Ayyukan mu na extrusion na al'ada suna ba da sassauci da inganci mara misaltuwa.

Zane da Tsari Tsari

T-slot aluminum profiles an yi su daga aluminum gami kamar 6063-T5 ko 6061-T6 ta hanyar zafi extrusion tsari. A lokacin extrusion, aluminum billlets suna mai zafi zuwa 450-500 ° C kuma ana tura su ta hanyar ƙira don samar da takamaiman sassan giciye. Halayen Ruiqifeng sun haɗa da:

- Babban madaidaicin girman iko (haƙuri tsakanin ± 0.1mm).

- Ƙarshen ƙasa mai laushi don sauƙin sarrafawa bayan aiki.

- Ma'auni na ƙarfi da ƙarfin hali, yana sa ya dace da tsarin ɗaukar nauyi.

Maganin Sama

Bayanan martaba na aluminum na masana'antu suna jure wa saman jiyya don haɓaka juriya da ƙayatarwa. Maganin saman gama gari sun haɗa da:

- Anodizing(Kauri Layer oxidation na 5-25μm, inganta juriya).

- Rufin Foda(akwai ta cikin launuka daban-daban).

- Rufin Electrophoretic(haɓaka taurin ƙasa da juriya na yanayi).

Aikace-aikace na T-slot Aluminum Profile

T-slot aluminum profiles ana amfani da ko'ina a:

- Masana'antu Automation(kamar firam ɗin layin taro).

- Kayan aikin Injini(kamar masu gadin inji da na'urorin gwaji).

- Kayan Wutar Lantarki(kamar kabad da racks uwar garken).

- Masana'antar Gine-gine(kamar tsarin goyon bayan bangon labule).

Hanyoyin Haɗin Bayanan Bayanan Aluminum

Bayanan martaba na aluminum suna ba da hanyoyin haɗin kai iri-iri, yawanci ta amfani da na'urorin haɗi na musamman ba tare da buƙatar walda ba. Wannan yana sa su zama abokantaka da muhalli da sauƙin haɗawa, haɗawa, jigilar su, da ƙaura. A cikin ƙirar al'ada, ana amfani da bayanan martaba na aluminum sosai.

Anan akwai hanyoyin haɗin kai guda 20:

- Gina-in Haɗi: An yi amfani da shi don haɗin 90 ° tsakanin bayanan martaba biyu; haɗin ɓoye tare da babban ƙarfi.

- Maƙallan kusurwa (90°, 45°, 135°): An yi amfani da shi don haɗin haɗin kusurwa na waje a 90 °, 45 °, da 135 °; iya amintaccen haše-haše panel.

- Screw Connection: An yi amfani da shi don haɗin ciki na 90 °; mai sauƙin shigarwa da cirewa, yawanci ana amfani dashi a cikin wurare masu sauƙi.

- Mai Haɗin Ramin L ɗin (90°): An yi amfani da shi don haɗin 90 °; mai sauƙin shigarwa kuma baya buƙatar ƙarin mashin ɗin.

- Babban Haɗin Ramin Ƙarfi (45°): An yi amfani da shi don haɗin haɗin 45 °; mai ƙarfi kuma galibi ana amfani dashi a cikin firam ɗin ƙofa.

- Ƙarshen Haɗin Fuskar: Ana amfani dashi don haɗin kusurwar dama tsakanin bayanan martaba biyu ko uku; m da aesthetically m.

- Mai Haɗin 3D (Kusurwar Dama): Ana amfani dashi don haɗin kusurwar dama tsakanin bayanan martaba guda uku; sauri da sauƙi.

- 3D Connector (R Angle): Ana amfani da shi don haɗin kusurwar dama tsakanin bayanan martaba guda uku masu lankwasa; sauri da sauƙi.

- Clip na roba: An yi amfani da shi don haɗin ciki na 90 °; sauki don shigarwa da cirewa.

- Ƙarshen Haɗi: An yi amfani da shi don haɗin ciki na 90 °; boye da kuma high-ƙarfi.

- Mai Haɗi madaidaiciya: Ana amfani dashi don haɗin layi mai ƙarfi tsakanin bayanan martaba biyu.

- Mai Haɗin Anchor: An yi amfani da shi don haɗin bayanan martaba tare da zaɓuɓɓukan kusurwa masu yawa; boye kuma dace.

- Daidaitacce Hinge: Ana amfani dashi don haɗin bayanan martaba, daidaitacce tsakanin 30°-150°.

- Farantin Haɗin Rotary: Ana amfani dashi don haɗin bayanan martaba daban-daban tare da jujjuyawar kusurwa da yawa.

- Farantin Haɗi: Ana amfani da shi don haɗin bayanan martaba da yawa; babban ƙarfi kuma yana buƙatar ƙarin mashin ɗin.

- Rotary Corner Bracket: Yana ba da damar haɗi a kowane kusurwa.

- Bolt Head Assembly: Saka ƙwaya mai roba a cikin bayanin martaba guda ɗaya da madaidaicin matsayi a cikin wani, an tsare shi da kusoshi.

- Farantin Haɗin Wuta Mai Siffar Ketare: Ana amfani dashi don haɗin ginin "+" mai ƙarfi.

- Nau'in L, T-Nau'in Farantin Haɗin WajeAn yi amfani da shi don haɗin ginin "L" ko "T" mai ƙarfi.

- Y-Nau'in Farantin Haɗin Waje: An yi amfani da shi don haɗin ginin "-" mai ƙarfi.

Ana iya nuna waɗannan hanyoyin haɗin kai ta hanyar zane-zane mai rai, yana sauƙaƙa wa injiniyoyi don zaɓar hanyoyin haɗin da suka fi dacewa yayin aikin ƙira.

Lokacin aikawa: Fabrairu-28-2025